SUNPERL PRODUCTS AS FILTER AIDS IN THE DEWAXING OF EDIBLE SUNFLOWER OIL

In the edible oil refining process, sunflower seeds are put through various steps to produce edible oil which can be used in cooking. The process consists of seed preparation and cleaning, pressing of the seeds to extract the oil, degumming, refining, bleaching, dewaxing and deodorization.

During the dewaxing process, the oil is cooled and filtered in order to remove the waxes and other impurities that crystallize during cooling. SunPerl products can be used for this filtration purpose.

The American Oil Chemists’ Society (AOCS) has set the standard for analytical methods critical to processing, trading, utilizing, and evaluating oils. These standards have been the globally recognised as the cornerstone of the edible oil industry making the Official Methods and Recommended Practices of the AOCS a requirement for all analytical standards within this industry.

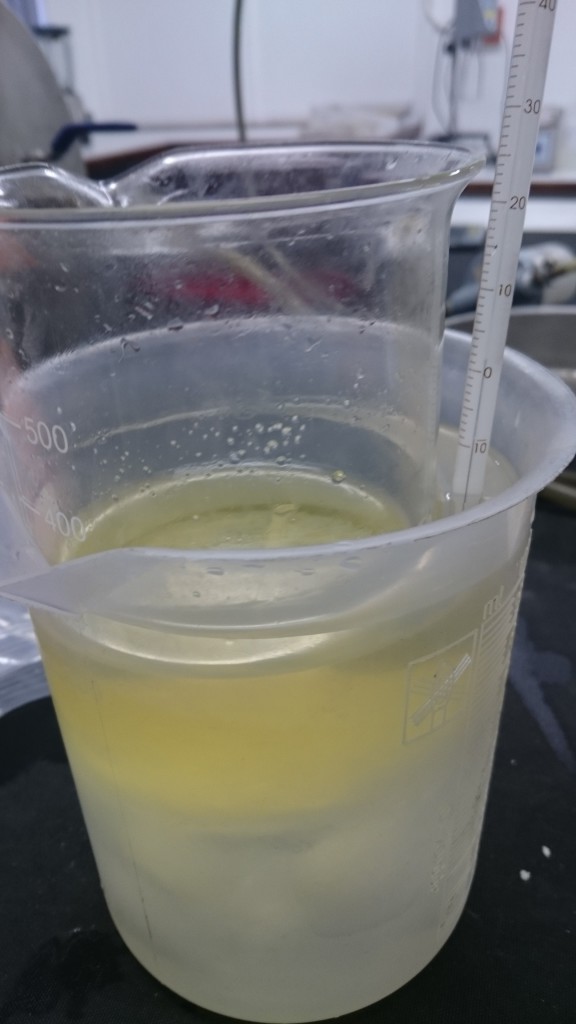

The effectiveness of SunPerl products in the oil filtration industry was evaluated in accordance with AOCS Method Cc 11 – 53. This procedure is also referred to as the cold test method or winterization. This method comprises of accurately weighing out 10g of the filter aid, which is then mixed with clean oil and filtered through a 125mm Buchner funnel under vacuum, in order to form a filter cake with a thickness no more than 5mm.

Lab scale setup

Photo: Gerbrand Haasbroek

SunPerl filtercake for winterization tests

Photo: Gerbrand Haasbroek

The bleached sunflower oil which is to undergo the dewaxing process is cooled to 12oC before a 250ml sample of the cooled oil is then poured onto the filter cake and filtered under vacuum at -60kPa. The filtered sample is then immediately placed in an ice bath and kept at 0oC for an extended period.

Temperature controlled ice bath

Photo: Gerbrand Haasbroek

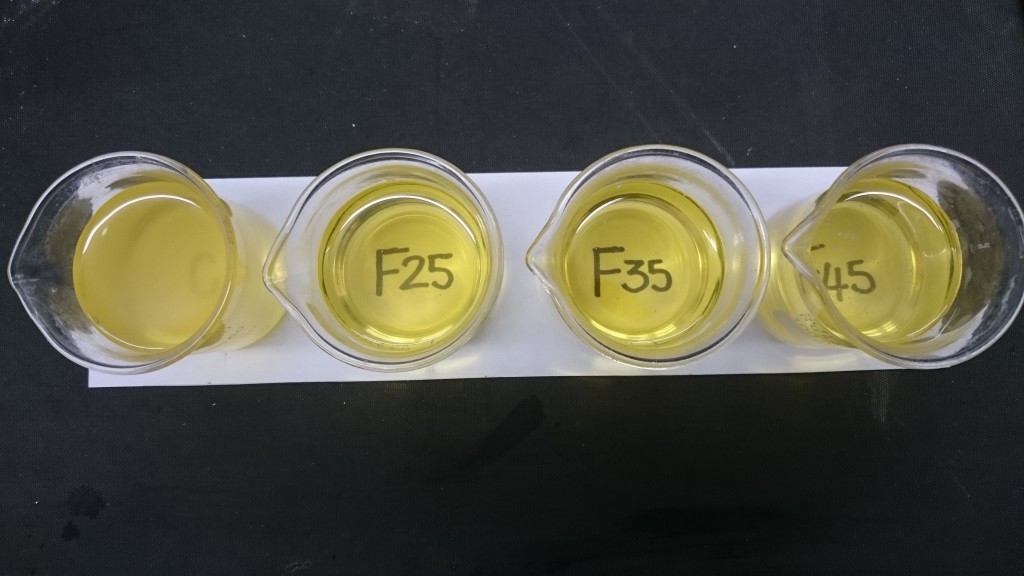

In order to pass the AOCS test, the sample should remain clear and free from cloudiness for at least 5.5 hours. A visual inspection can be used as a first indication of the dewaxing that was achieved with these products. In the image below the Sunperl products are visually compared to the control sample on the left.

Filtered oil samples after 5.5 hours at 0oC

Photo: Gerbrand Haasbroek

Our laboratory trials have indicated that the oil samples eventually show a slight cloudiness indicating that the waxes and other impurities are not completely removed, however the samples filtered with SunPerl products remain free from cloudiness for up to 8 hours, indicating that enough waxes were removed to make these products suitable for industrial applications related to the filtration of edible oils.

The rate of filtration is also considered an important parameter. The range of SunPerl filter aids we manufacture are classified based on the filtration rate that can be achieved. The balance between the filtration rate and the clarity of the filtered oil is individually evaluated for each of our customers based on the properties of the oil and the process conditions.

For more information, please contact Sun Silicates (Pty) Ltd, or visit our website www.sunsilicates.co.za

No Comments