INMIM EQUIPMENT DESIGN AND MANUFACTURING

A QUICK INTRODUCTION

INMIM is a privately owned company that forms part of the Sun Silicates group, a group of companies that mine, process and manufacture a variety of high tech products. The group works from their head office in Wadeville Germiston were the use of the common infrastructure, ensure high quality products at competitive prices.

INMIM was formed after engineers at Sun Silicates had the need to design their own processes and build tailor made equipment due to high design and manufacturing costs of specialised equipment. INMIM has low overhead costs and the capability to design and manufacture nearly any component at a fraction of market related design & manufacturing costs.

The company is owned by a father and son team; both being qualified Metallurgical engineers from the University of Pretoria. Over and above the experience gained in their own businesses, their experience includes experience of the Vanadium, Ferro chrome, Ferro Manganese, coal, aluminium, iron & steel, chrome and PGM industries. The experience includes not only process management but also design, construction and project management.

INMIM specializes in innovative design, equipment manufacturing, process design & optimisation, manufacturing & commissioning of industrial equipment. INMIM focuses on small to large sized companies that need cost effective and purpose made equipment. INMIM is committed to service, quality & efficiency and strives to exceed your expectations.

For support INMIM also employs Metallurgical, Chemical and Mechanical engineers. Giving them the ability to design, draft, manufacture and commission equipment made purposefully for the Metallurgical, Chemical and other industries.

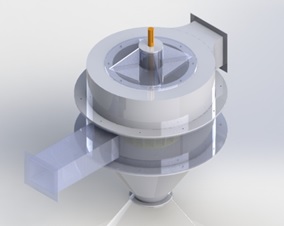

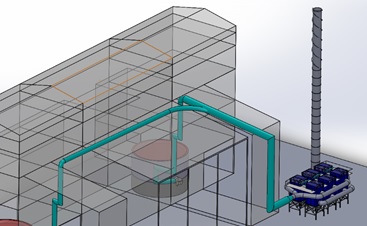

Equipment is designed in-house on 3D software enabling the customer to visually inspect products before manufacturing commences and allows products to be modified to the specific process requirements.

3D CAD DESIGNS

3D CAD design – Classifier

3D CAD design – Fume extraction plant with baghouse system

INMIM’s metallurgical and mechanical engineers can evaluate/measure process parameters in the customer’s plant and then determine the design criteria required for the equipment, this includes: air flow, humidity, temperature, mass flow and other parameters. Complete process design service is also conducted where required.

Process instrumentation

Photo: Gerbrand Haasbroek

Equipment is manufactured according to standard specifications, special finishing can be applied to any equipment parts, i.e. powder coating, galvanising, sand blasted, etc. Manufactured equipment undergoes inspection & testing to ensure the product meets design specification resulting in sound quality & client satisfaction. Once equipment is manufactured installation and commissioning can be provided as required by the customer. INMIM also provides complete process control systems, tailor made for processes and commissioned, these include: variable speed control, temperature control, automation, etc.

Products previously manufactured include, but are not limited to:

• Rotary valves

• Bag houses

• Screw conveyors

• Impact crushers

• Ribbon blenders

• Product coolers

• Rotary kilns/driers

• Air cyclone separators

• Classifiers

• Electrical control panels

• Coal stoker heating systems

• Exfoliators

• Fume / dust extractors

From left to right: Exfoliation plant; Baghouse unit; Rotary valve; Conveyors

Photo’s: Gerbrand Haasbroek

Using INMIM ensure that your project is soundly designed while ensuring cost effectively solutions that cater for the ergonomics’, safety and process requirements of the facility.

For more information, please contact INMIM or visit our website www.sunsilicates.co.za/equipment-manufacturing/

No Comments